How I Read the Market Before Buying Equipment — A Smarter Play for Entrepreneurs

Every time I upgrade machinery, I’m not just spending—I’m betting on the future. Get it wrong, and you’re stuck with underused gear and tight cash flow. Get it right, and your business runs smoother, scales faster. Over the years, I’ve learned that timing equipment purchases isn’t about need alone—it’s about reading trends, anticipating shifts, and avoiding emotional decisions. This is how I stay ahead without gambling my capital. The truth is, most entrepreneurs buy equipment based on immediate pressure: a broken machine, a sudden spike in orders, or the fear of falling behind. But those reactions often come at a cost. Delayed decisions lead to downtime. Rushed ones lead to overspending. The smarter path lies in stepping back, observing the broader picture, and making moves based on insight rather than urgency. This approach doesn’t eliminate risk, but it transforms procurement from a reactive expense into a strategic investment.

The Hidden Cost of Buying Too Soon (or Too Late)

Equipment purchases are among the largest financial commitments a small or mid-sized business makes. Yet, many of these decisions are driven more by circumstance than strategy. The real danger isn’t just in making the wrong choice—it’s in failing to recognize the long-term financial consequences of mistimed decisions. Buying too early can lock up capital in assets that sit idle or depreciate rapidly before they deliver full value. Buying too late can mean missed opportunities, operational bottlenecks, and an inability to meet customer demand. Both scenarios erode profitability, but in different ways.

Consider a manufacturer who invests in a high-speed packaging line after a single quarter of increased sales. The machine costs $250,000, financed over five years. But if the sales surge was temporary—driven by a short-lived trend or a one-time contract—the new equipment may operate at only 40% capacity for months. The fixed payments continue regardless, straining cash flow. Meanwhile, maintenance costs rise, and the machine begins to depreciate. Within three years, a newer, more efficient model enters the market, making the early adopter’s investment partially obsolete. The initial gain in speed is offset by long-term inefficiency and higher per-unit operating costs.

On the other hand, waiting too long can be equally damaging. A logistics company that delays upgrading its fleet may continue using older diesel trucks that consume more fuel, require frequent repairs, and face increasing regulatory scrutiny. By the time they act, fuel prices have risen, and newer emission-compliant models are in high demand, driving up prices. They also face downtime during the transition, losing delivery capacity at a critical time. The cost of delay isn’t just the higher purchase price—it’s the cumulative impact of higher operating expenses, reduced reliability, and lost business opportunities.

The opportunity cost of poor timing is often overlooked. Capital tied up in underutilized equipment could have been used for marketing, staff training, or research and development. Conversely, delayed investment may force a business to turn down profitable contracts due to capacity constraints. Depreciation is another silent drain. Equipment typically loses value from the moment it’s purchased, and the steepest decline often happens in the first two to three years. A well-timed purchase minimizes exposure to this loss while maximizing utility. The goal isn’t to avoid equipment investment—it’s to align it with actual, sustained business growth rather than temporary fluctuations.

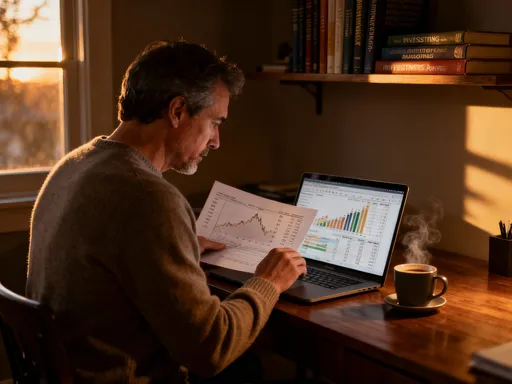

Why Trend Judgment Beats Gut Feeling in Equipment Planning

Many entrepreneurs pride themselves on their intuition. In fast-moving markets, quick decisions can feel necessary. But when it comes to capital expenditures, relying on gut feeling alone is a recipe for financial strain. Emotional decisions—driven by fear of missing out, pressure from competitors, or the desire to appear innovative—often lead to premature or unnecessary purchases. A smarter approach replaces instinct with insight, using data and observable patterns to guide procurement.

Market trends provide a more reliable foundation than personal judgment. For example, rising input costs—such as raw materials or energy—can signal upcoming shifts in production efficiency. If electricity prices are climbing steadily, it may be time to consider energy-efficient machinery, even if current equipment still functions. Similarly, changes in labor availability can influence the value of automation. In regions where skilled labor is becoming scarce or expensive, investing in semi-automated systems may offer a faster return than hiring additional staff.

Macroeconomic indicators also play a role. Interest rates, for instance, directly affect financing costs. Purchasing equipment during a period of low interest rates reduces the long-term cost of borrowing. Conversely, buying during a credit crunch can lead to higher payments and tighter cash flow. Industry-specific cycles matter too. Construction, agriculture, and manufacturing all experience demand fluctuations based on seasons, commodity prices, or government policies. A business that monitors these cycles can time its equipment upgrades to coincide with periods of expected growth, rather than scrambling during peak demand.

Technological advancements are another critical signal. Not every new feature justifies an upgrade, but ignoring innovation can leave a business behind. The key is to distinguish between incremental improvements and transformative changes. For example, a new software update for a CNC machine may offer minor efficiency gains, while the introduction of AI-driven predictive maintenance could significantly reduce downtime and repair costs. Trend judgment involves evaluating not just what’s new, but whether it creates meaningful operational advantages. This shift—from reactive purchasing to proactive planning—transforms equipment investment from a cost center into a strategic lever for growth.

Reading the Signals: What Smart Buyers Watch For

Successful equipment procurement begins long before the purchase order is signed. It starts with continuous observation. Smart entrepreneurs don’t wait for a crisis to act—they monitor a set of leading indicators that reveal when it’s time to upgrade, expand, or hold off. These signals are not always obvious, but they are measurable and reliable when tracked consistently.

One of the most telling signs is supply chain stability. If suppliers are experiencing longer lead times, material shortages, or price volatility, it may indicate broader industry strain. For some businesses, this is a warning to delay non-essential purchases. For others, it’s a signal to act early—securing equipment before availability tightens and prices rise. For example, a food processor noticing delays in stainless steel components might decide to order a new mixing system ahead of schedule, locking in current pricing and ensuring delivery before a potential bottleneck.

Input costs are another key metric. When the price of energy, raw materials, or transportation increases, it affects the cost-effectiveness of existing equipment. A printing company facing higher ink and paper costs might find that upgrading to a digital press—despite the upfront cost—reduces waste and improves turnaround time, leading to better margins. The decision isn’t based on the machine’s novelty, but on its ability to offset rising operational expenses.

Labor trends also influence equipment decisions. If a business struggles to hire skilled operators or faces rising wages, automation becomes more attractive. A bakery that once relied on hand-formed pastries may find that investing in a shaping machine improves consistency and reduces dependency on hard-to-find talent. The trigger isn’t just labor cost—it’s the predictability and scalability that automation offers.

Competitor behavior provides additional context. If multiple players in an industry are adopting similar technology, it may signal a shift in customer expectations or efficiency standards. A roofing contractor noticing that peers are using drone-based measurement tools might realize that manual estimates are becoming a competitive disadvantage. The goal isn’t to follow the crowd blindly, but to understand whether new tools are delivering real benefits. By watching these signals—supply chain dynamics, input costs, labor markets, and competitor moves—entrepreneurs can make informed decisions that align with actual market conditions, not just internal pressures.

Matching Technology Lifecycles to Your Growth Curve

Not all technologies are created equal, and not every innovation is right for every business at every stage. The lifecycle of a technology—its introduction, growth, maturity, and eventual decline—should align with the growth phase of the company. Misalignment can lead to wasted investment or missed opportunities.

Early adopters often pay a premium for new equipment. They benefit from first-mover advantages, such as improved efficiency or enhanced branding as an innovator. But they also face higher risks: unproven reliability, limited service support, and the possibility that the technology will be quickly superseded. A small textile mill that invests in a prototype dyeing system may gain a temporary edge, but if the technology fails or evolves rapidly, the initial investment may not deliver a return. Early adoption makes sense only when the benefits outweigh the risks and when the business has the resources to absorb potential setbacks.

In contrast, late adopters avoid the pitfalls of untested technology but risk falling behind. By waiting too long, they may miss out on efficiency gains that competitors use to lower prices or expand capacity. A mid-sized furniture maker that delays adopting CNC routing technology may struggle to match the precision and speed of rivals, losing market share over time. The sweet spot lies in the growth phase of the technology lifecycle—when the product is proven, service networks are established, and prices have stabilized but before it becomes standard across the industry.

A company’s own growth trajectory must also be considered. A startup with limited cash flow should prioritize essential, reliable equipment over cutting-edge options. As the business scales, it can reinvest profits into more advanced systems. A scalable approach might involve starting with modular machinery that can be upgraded later, rather than buying a full-featured system upfront. This way, the business grows into its technology, rather than being burdened by it. Matching the technology lifecycle to the company’s stage ensures that investments are both timely and sustainable.

The Cash Flow Balancing Act: Paying for Tools Without Breaking the Bank

Even the best-timed equipment purchase can strain a business if not financed wisely. Cash flow is the lifeblood of any operation, and large capital expenditures can disrupt it if not managed carefully. The challenge is to acquire necessary tools without jeopardizing liquidity or limiting future flexibility.

One of the most important decisions is whether to buy or lease. Purchasing outright gives full ownership and long-term cost control, but it requires a significant upfront investment. Leasing, on the other hand, spreads the cost over time and preserves cash for other needs. It also allows businesses to upgrade more frequently, staying current with technology. However, leasing means never owning the asset and potentially paying more over time. The choice depends on the business’s financial health, tax situation, and long-term plans.

Vendor financing programs can offer attractive terms, such as low-interest rates or deferred payments. These can make high-cost equipment more accessible, especially during periods of expansion. However, they should be evaluated carefully—fine print matters. A seemingly low monthly payment might come with a large balloon payment at the end, creating a future cash crunch. Similarly, some deals include maintenance packages that seem convenient but may be overpriced compared to independent service providers.

Staggered investment is another effective strategy. Instead of replacing an entire production line at once, a business might upgrade one component at a time. This reduces the immediate financial burden and allows the team to adapt gradually. It also provides time to evaluate the performance of new equipment before committing to further upgrades. For example, a packaging company might start by automating the labeling process, then move to filling, and finally to boxing—each step funded by the savings generated from the previous one.

Maintaining financial flexibility is crucial. Unexpected market shifts—such as supply chain disruptions or sudden demand changes—require the ability to adapt. A business that ties up all its capital in equipment may struggle to respond. By preserving liquidity through smart financing, entrepreneurs ensure they can navigate uncertainty without sacrificing long-term growth.

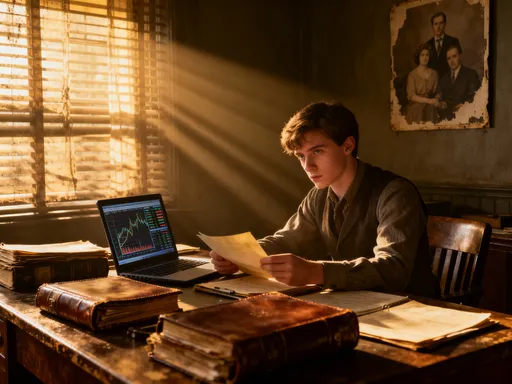

Learning from Others: Real Cases of Timing Wins (and Losses)

Real-world examples offer powerful lessons in equipment procurement. While every business is different, the outcomes of well-timed and poorly timed decisions reveal clear patterns. These anonymized cases illustrate how trend awareness can lead to success—or how ignoring signals can result in avoidable setbacks.

In the manufacturing sector, a mid-sized metal fabricator faced increasing demand in 2021. Instead of rushing to buy new laser cutters, the owner analyzed industry trends. He noticed that steel prices were rising and supply chains were strained. He also observed that competitors were expanding rapidly, which could lead to oversupply. Rather than investing in new equipment, he optimized existing machines, improved scheduling, and outsourced overflow work. When demand slowed in 2023, many competitors were left with idle capacity and heavy debt. His cautious approach preserved cash and positioned him to acquire used equipment at a discount when the market stabilized.

Another example comes from the logistics industry. A regional trucking company delayed upgrading its fleet for several years, relying on older vehicles to save costs. But as fuel prices climbed and maintenance expenses increased, profitability declined. In 2022, they finally purchased new, fuel-efficient trucks—just as diesel prices peaked. The timing amplified their costs. A more strategic approach would have involved monitoring fuel trends and replacing vehicles in phases during a period of lower prices. Instead, the delayed decision turned a necessary upgrade into a financial burden.

In the service sector, a commercial cleaning business successfully anticipated labor shortages. In 2020, they began investing in automated floor scrubbers and vacuum systems. At the time, the cost seemed high, but as minimum wages rose and hiring became difficult, the investment paid off. They maintained service levels with fewer staff, improved consistency, and even expanded into new contracts. Their foresight turned a capital expense into a competitive advantage.

These cases show that success isn’t about avoiding equipment investment—it’s about making informed, timely decisions. The winners were those who looked beyond immediate needs and aligned their purchases with broader market conditions. The losses came from reactive thinking, emotional pressure, or a failure to monitor key indicators. The lesson is clear: procurement strategy matters as much as the equipment itself.

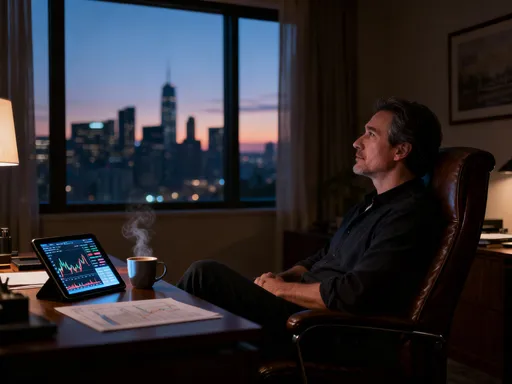

Building a Forward-Looking Equipment Strategy

Smart equipment procurement isn’t a one-time event—it’s an ongoing discipline. The most successful entrepreneurs treat it as a core part of their business planning, not an afterthought. They integrate trend monitoring into regular reviews, set clear criteria for action, and cultivate a mindset of strategic patience.

The first step is to establish a routine for tracking key indicators. This might include monthly reviews of input costs, quarterly assessments of industry trends, and annual evaluations of equipment performance. Some businesses create a simple dashboard that tracks metrics like machine utilization rates, maintenance costs, and competitor activity. This data-driven approach removes emotion from decision-making and provides an objective basis for action.

Next, define trigger points for procurement. Instead of reacting to breakdowns or sales spikes, set thresholds based on performance and market signals. For example, if machine downtime exceeds 10% of operating hours, or if labor costs rise above a certain percentage of revenue, those could be signals to explore automation. If competitor adoption of a new technology reaches 30% in the industry, it might indicate that the technology has reached maturity and is worth evaluating.

Finally, foster a culture of strategic thinking. This means involving key team members in the decision-making process, encouraging them to report operational inefficiencies, and rewarding long-term planning over quick fixes. It also means being willing to wait. In a world that values speed, the ability to delay a purchase until the timing is right is a rare but powerful advantage.

Over time, this disciplined approach transforms how a business grows. Equipment investments become predictable, efficient, and aligned with real needs. Capital is protected, productivity improves, and the business gains the agility to respond to change. This isn’t about chasing the latest technology—it’s about making thoughtful, well-timed decisions that support sustainable success.

Procuring equipment is more than a transaction—it’s a strategic forecast. When you align purchases with real trends, not just immediate needs, you protect capital, boost productivity, and position your business to move faster than competitors. It’s not about having the newest tools; it’s about having the right ones at the right time. That’s how sustainable growth takes root.